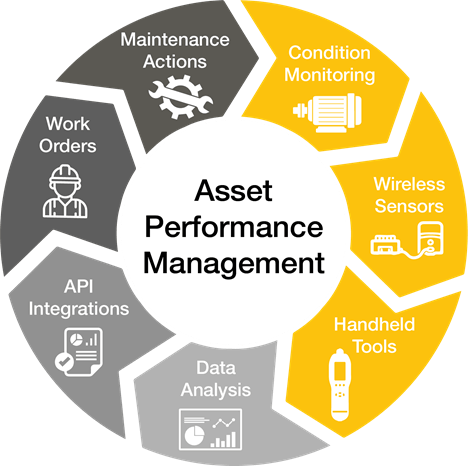

Asset performance management (APM) encompasses the capabilities of data capture, integration, visualization and analytics tied together for the explicit purpose of improving the reliability and availability of physical assets. APM includes the concepts of condition monitoring, predictive forecasting and reliability-centered maintenance (RCM).

Our Actions

Use an IoT and AI platform to help predict when asset degradation or failure might occur. Correlate factors such as historical and real-time asset performance data, maintenance records, inspection reports and environmental data.

Transform your approach by driving actions based on the current health of your assets. Monitor factors such as condition, cost, performance and remaining useful life. Define scoring methods, prioritize areas of focus and initiate maintenance activities.

Remotely monitor critical assets and operations with AI-powered monitoring at enterprise scale. Aggregate operating state and IT data with process parameters across repositories to provide enterprise-wide visibility into performance and receive fewer, more accurate alerts and greater insights.

Optimize asset maintenance and replacement strategies based on asset risk and criticality. Determine how to better manage inspections and maintenance, optimize repair and operations inventories, and prioritize replacement versus repair decisions.